A Metrics Model for Supply Chain Organizations

A critical challenge for many organizations is to implement a proven governance model that can integrate management strategies with internal and external metrics to optimally steer the organization. In the supply chain industry, there are many business capabilities common across organizations. So, it makes sense to use an industry-standard metrics model, customized to the organization if necessary.

However, I see many organizations using ad hoc or homegrown metrics to manage their operations. Even within an organization, different individuals may have a different understanding of the same metrics. As a result, it is difficult to implement industry best practices in that organization, and frequently leads to poorer performance of the business. Indeed, it is like a group engaged in conversation, but having no common language!

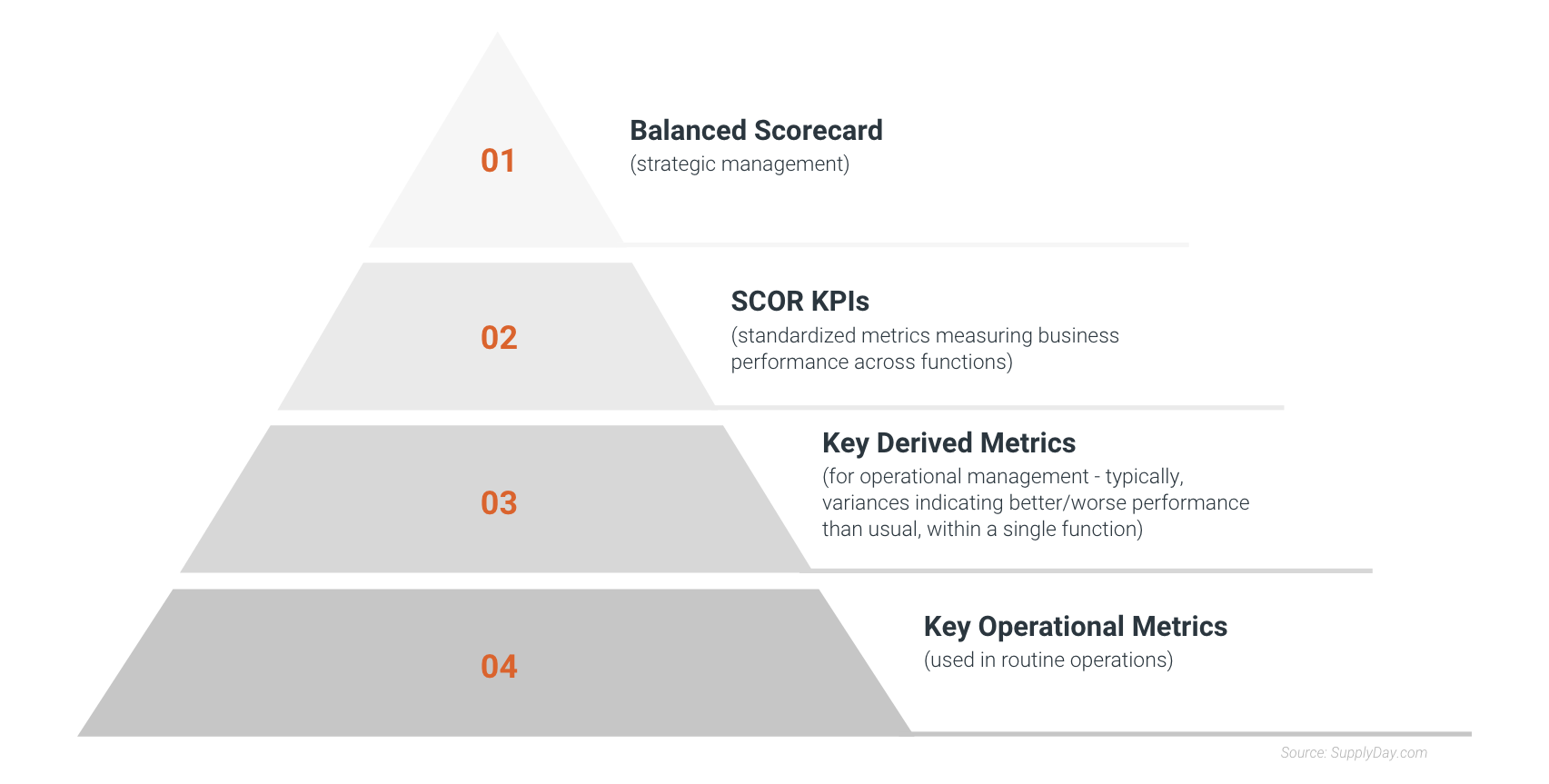

A Four-Layer Metrics Framework

Is there really any metrics model that can apply to all supply chain organizations – one size fits all? Yes, and no! We need to have operational metrics that capture the unique aspects of each organization, in their own terminology if necessary. Yet, we need to map those metrics to the basic building blocks of a supply chain, which are the same when seen at a higher level of abstraction. Therein lies the answer: We need a multilayered metrics model. To cater to all the demands placed on the metrics model, I use a four-layered framework:

- Key Operational Metrics form the lowest layer of this framework. They can be unique (or customized) to an organization and are recorded and used by staff in their routine operations.

- Key Derived Metrics form the next higher layer. They are derived from the operational metrics, and help operational managers and supervisors manage the performance of business processes. Typical derived metrics include variances, or deviation from the norm, and aggregates of the operational metrics.

- Industry-Standard Metrics form the third layer of the framework and are the common across all organizations. These standardized metrics are mapped to the derived metrics in the second layer, to create a holistic model of the organization that can be compared with other supply chain organizations.

- Strategic Metrics form the fourth and topmost layer of the framework. These may take the form of a Balanced Scorecard (BSC) and represent the performance indicators at the corporate level. Dissociating the strategic metrics from the operational metrics also forces business strategies to be defined at a conceptual level, avoiding the pitfall of identifying a means as an end.

Using SCOR to Standardize Supply Chain KPI Metrics

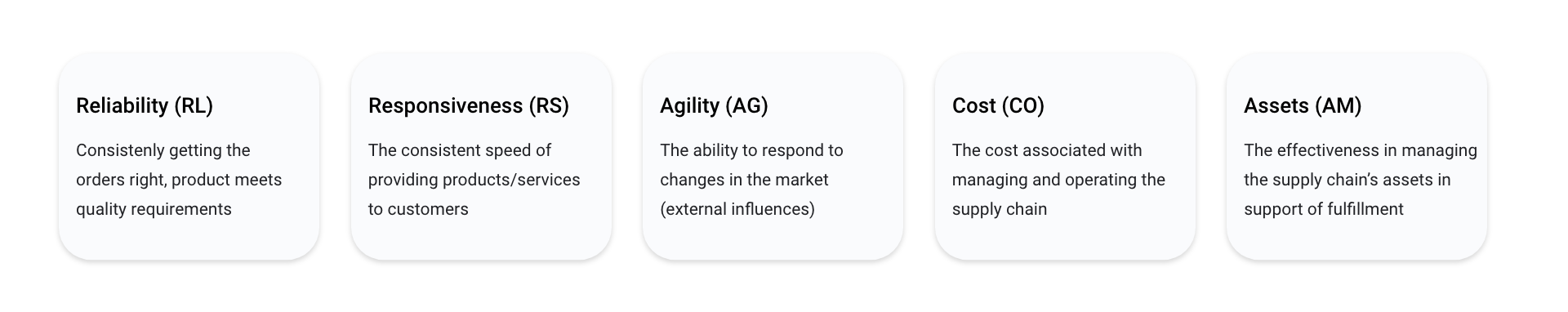

Operational and derived metrics (layers 1 and 2) may already be defined in an organization or can be identified by analyzing each major process for input, output and quality measurement criteria. For industry-standard metrics (layer 3), we can use a model such as SCOR (Supply Chain Operations Reference). SCOR provides a set of key performance indicators based on five core performance metrics: reliability, responsiveness, agility, costs and asset management, as shown. These SCOR metrics have standard calculations, and lower-level metrics that can be used by any supply chain organization. You can find out more about SCOR at the APICS website.

In this way, we can implement a metrics model for supply chain operations that provides comprehensive coverage from strategy to operations, is customized to the organization, yet mapped to industry standards, and is not overly complex.