Robotic Process Automation is Easing the Daily Grind of Supply Chain Management

Robotic Process Automation (RPA) involves use of software ‘robot’ programs to automate manual operations that have traditionally been difficult to automate. For example, RPA can be used to automate a process involving extraction of information from paper-based forms, applying rules and calculations, and updating other systems by simulating human user interactions.

The most obvious advantage of RPA is efficiency. Based on a study by ISG, RPA is driving average cost savings of 37% by automating manual processes. Reduction of errors and risk is another major benefit. Processes executed using RPA are inherently more manageable, and metrics are captured seamlessly. RPA is also a big enabler of business growth by enhancing the scalability, flexibility and integration of business processes.

RPA in Supply Chain Management

Some of the common use cases of RPA are in business functions such as accounting and HR, which are applicable to most business domains. However, there are several aspects of supply chain management, which are very well-suited for RPA. These include customer relationship management & ordering, supplier relationship management & procurement, transportation & logistics, and supply & demand planning.

Customer Relationship Management and Ordering

Many businesses utilize separate information systems for business functions such as CRM, sales/ordering, and accounting. Customer data may be updated in multiple systems and may need to be synchronized. For example, the accounts department may ‘flag’ a customer for a bounced check, or the customer service department may flag the customer for inappropriate behavior. This may further require suspension of the customer’s ordering privileges on the web portal until the account manager is notified and reviews that customer account. Such manual tasks spanning multiple information systems are a prime candidate to automate using RPA. Order management is another critical business process where RPA can help greatly. For example, by automatically entering emailed of faxed orders into an ordering system.

Supplier Relationship Management and Procurement

To minimize risks, optimize the product mix and reduce procurement costs, it is often necessary to adjust supplier relationships. The processes involved include monitoring the performance of existing suppliers, selecting new suppliers and negotiating contracts. These processes typically have many manual steps, such as forms to be filled, documents to be created and messages to be sent. RPA can automate these manual tasks, and even take rules-based decisions, leaving discretionary decisions to humans, so that effort involved is minimized.

Keeping product catalogs up-to-date may also require extraction of product information from a diverse set of supplier catalogs. This can be a challenge because many suppliers, especially smaller ones, may not offer an electronic catalog in a standardized format. For any given supplier, the products offered (and their prices) vary over time, so the catalog needs to be ‘refreshed’ on a consistent basis. If the supplier no longer offers a desired product, or if the price is no longer competitive, the product may need to be sourced from a different supplier, or perhaps even discontinued. In this scenario, manual effort is generally required to extract the information from new supplier catalogs, compare it to existing records, and to take decisions based on product and price changes detected in the catalogs. This process can benefit greatly from RPA, as the effort, cost, and time taken for updating supplier catalogs would be greatly reduced, and the error rate would also decrease. Notifications can also be generated automatically based on business rules.

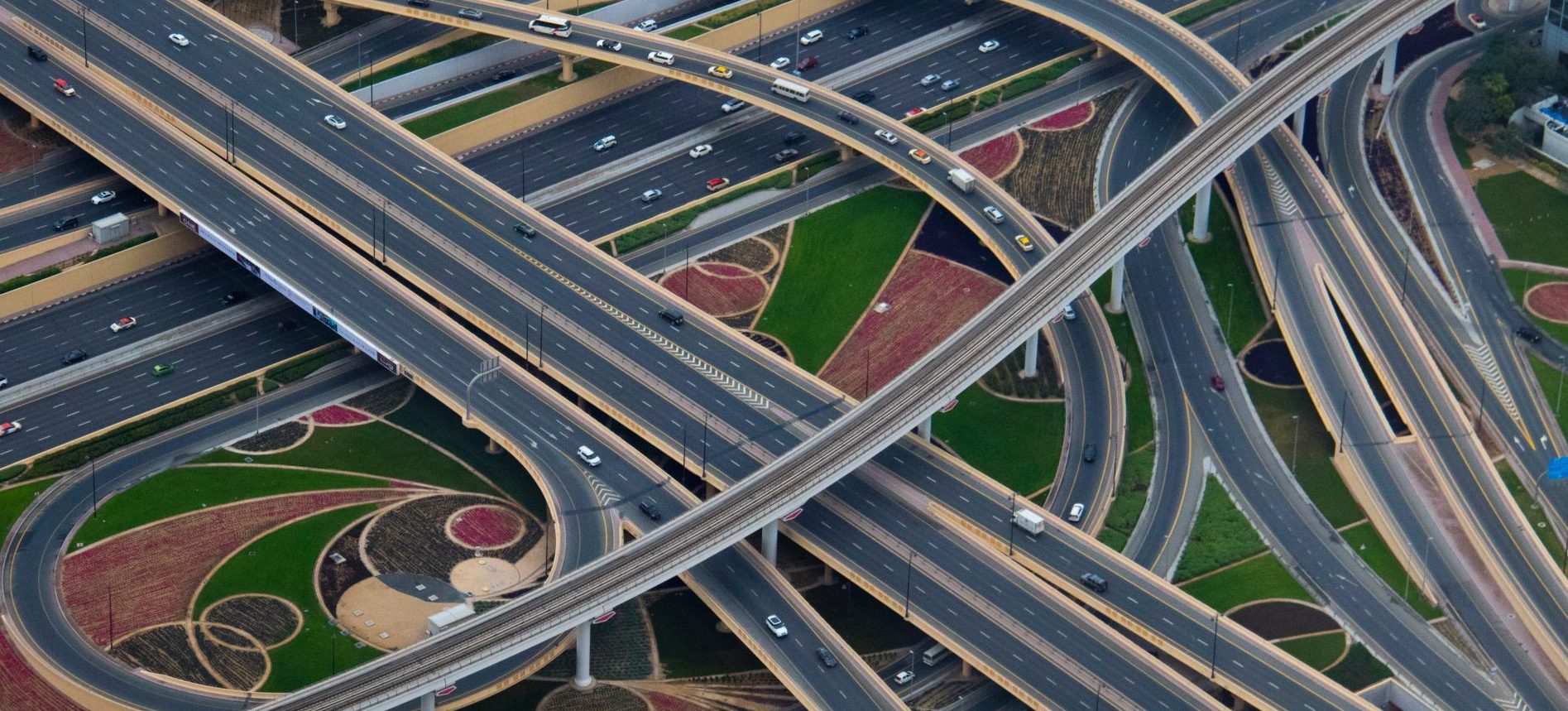

Transportation and Logistics

In transportation and logistics, scheduling and tracking shipments involves many manual tasks that typically require staff to work with multiple forms, labels, applications, websites, etc. Information is managed in electronic or paper-based documents such as bill of lading, proof-of-delivery and invoices. Automation of such tasks allows accurate and real-time tracking of shipments, which further aids planning.

Returns management is another key aspect of logistics, as 4% to 6% of all retail sales are typically returned by customers. Further, returns may also be necessary to contracts governing unsold goods, or for recalls and recycling. As supply chains mature, and increased focus is put on customer experience and sustainability, these reverse logistics processes have become very important, and traceability of products during the returns process is also important. However, due to the tremendous diversity in customer behaviors and retail outlets (including resale scenarios), the provenance information accompanying returned products may be poor in heterogeneous formats and poor in quality. This information is an important factor in making decisions regarding refunds, recalls, restocking, discarding, process improvement, and more. Ignoring the information that can be gleaned from returns can expose the business to unnecessary risks. As a result, significant manual effort may be spent to manage this information. For example, extracting information from hand-filled return forms and correlating/analyzing it to detect patterns.

This is a very good use case for RPA, as software robots can be used automate such returns processing flows. For example, the RPA solution can perform OCR on hand-filled return forms, identify common/related reasons for returns and correlate them with other logistics information to identify probable causes, such as improper handling or refrigeration.

Supply and Demand Planning

Supply and demand planning are other good candidates for RPA, since they require aggregating data from multiple sources to take decisions. For example, to optimize the purchase orders, the purchase plan needs to be created by incorporating factors such as sales history, sales targets, price trends, seasonal fluctuations, current inventory levels, shipments expected (Advance Shipping Notices), product roadmaps, etc. Correlation of all this data can be challenging and consuming. Further, rules, corrections and notifications may need to be applied, and the entire process needs to be repeated frequently. Using RPA, the effort required, and the risk of errors can be greatly reduced. Additionally, the automated process can be repeated reliably, making it tremendously easier to optimize it in each planning iteration.

Too Good to be True?

So, is the hype about RPA justified, or is it too good to be true? Are there hidden risks and caveats that technology evangelists inevitably understate? These questions have been answered over the past few years as RPA has gained momentum, and there are numerous implementations in the industry. Surprisingly, the results have been overwhelmingly positive. RPA is a rare instance of a technology delivering well on its hype. However, the supply chain industry is still in an early stage when it comes to RPA adoption… and early-adopters are gaining competitive advantage. So, if you have been thinking about RPA, the best time to jump in (or at least get your feet wet) is now!